The use of the wire rod scraper coating machine is still relatively convenient and simple, including several steps: switching on and off, operation settings, wire rod installation, scraper film thickness adjustment, and coating.

The following is the specific operation method:

1. Switch machine

1) Power on: Connect the power supply and press the switch button to turn it on.

2) Shutdown: Press the switch button to shut down, and then disconnect the power supply.

2. Operation panel

1) Speed setting: The coating speed of the film coating machine can be steplessly adjusted between 0 and 250mm/s. Click the blank box of the coating speed, enter the speed value, and click OK.

2) Film length setting: The coating speed of the film coating machine can be set between 0 and 400mm. Click the blank box of the film length, enter the value, and click OK.

3) Operation: After setting the coating parameters, click "Film Coater" to automatically scrape.

4) Reset: After coating, click "coating head" to return to the original position.

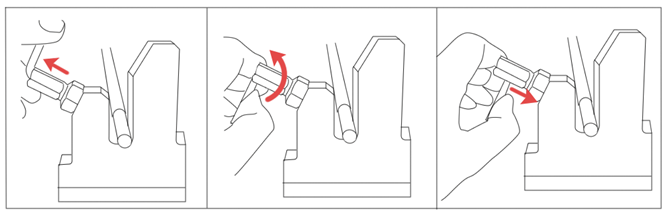

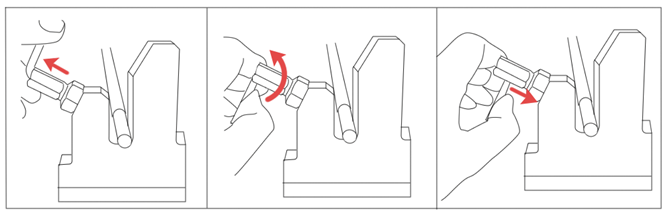

3. Wire rod installation

1) Pull the L handle at both ends of the clamping rod in the direction of the body to release the rod.

2) You can turn the L handle to the left or right, and then turn the L handle down after placing the wire rod to fix it.

4. Scraper operation

1) Leveling scraper: first tighten the knob plungers at both ends to level the scraper down

2) Set the film thickness: Control the film thickness through two differentiators, short press the on/OFF--SET button of the differentiator to start the digital differential, and then long press the on/OFF--SET button to zero. Rotate the differential regulator counterclockwise to adjust the film thickness required for the experiment, the default unit is mm.

3) Scraper cleaning: The scraper adopts a clamshell design, directly turns the entire scraper to the left, and then wipes it quickly with a suitable solvent and a soft rag. Be careful to lift the scraper lightly.

5. Fixture operation

Rotate the black knobs at both ends of the clamp, and there are springs between the clamps to bounce the upper clamp, easily put the substrate on the platform, and then tighten it.

6. Coating operation

1) Place the substrate on the coating table and fix it with a fixture.

2) Install a coating rod with a suitable film thickness or adjust the film thickness of the scraper;

3) Apply the scraped sample before the wire rod/scraper;

4) Set the coating speed and coating length.

5) Click "Run" to start scraping;

6) After scraping, lift the wire rod or raise the scraper to remove the coating sample;

7) Cleaning rod/scraper and coating table.